Start build or should it be NOT start build - Innellan 1st May

Start build or should it be NOT start build

This past few months have been a total roller coaster, a

mixture of problems with Gwen, numerous visits to and from Dover to check on

her ability to cope and the tardiness of the structural engineer. The latter continues

to cause problems, although the biggest mistake was to disappear last winter to the USA.

The engineers are so busy with work that any excuse allows them to put our work on the

back burner. We had planning permission

back in August 2015 and the structural engineer should take about two to three

months to prepare their calculations and submit them to the building control.

Obviously, nothing happened until we came back in March.

Since then we have had to amend and alter the design to take

into consideration various problems. Realistically most have been due to

suppliers being rather backward in thinking up in Scotland. Practices and

methods often adopted in the South are not norm, so they are not readily

available.

This was most evident with the block and beam flooring. In

the south there is a method of using reinforced insulation blocks in between

the concrete beams, therefore reducing the amount of work whilst providing far

greater insulation. The companies in Scotland have never used the method and

therefore would not guarantee the product being used in this situation. Very

frustrating, especially when many of the companies in Scotland are sister

companies of those in the south who are phisically promoting the product.

| Tetris system with insulation blocks |

The companies in the south were happy to provide, but the shipping

costs put the product out of contention.

Other suggestions were put forward as being more cost

effective, but once the cost of extra reinforced concrete had been put into the

mi the cost doubled.

| tata steel alternative |

Eventually we had to revert to block and beam, with

insulation over and reinforced concrete on top, and ultimately more insulation

under the beams.

| Standard block and beam system |

As you can appreciate the constant changing of product had

an effect on the design, the way it was laid and fitted to. Plus the depth had

effect on head height on the ground floor. Something that is still outstanding,

and it’s the 1st of May today.

But then again, this is tied up with the tanking in the

reinforced wall on the ground floor.

Perhaps l ought to start at the beginning, to lay the

foundations out so to speak.

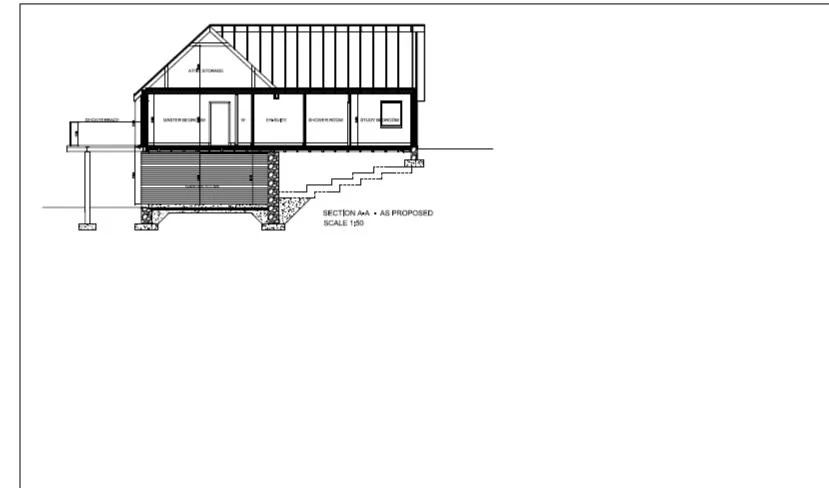

Because of the severe slope we had two choices. We either

cut out terraces and built foundation walls and build them up to the first

floor level. Much as was done in our present house, which proved to be very

expensive. Or the method that we eventually chose to go down. Using steel

pillars that supported the main first floor slab which the timber kit home

bolted onto.

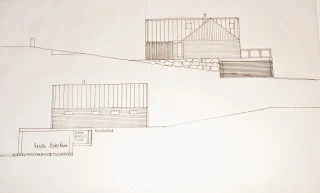

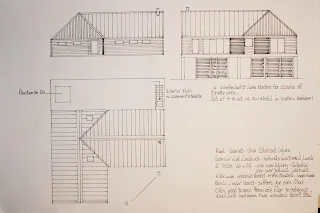

initial thoughts that l ran passed the local planners.

We were exceedingly

surprised to find out that the planners were happy with all our initial intentions.

Steel roof, larch cladding, narrow windows, extended balcony and elongated

footprint.

So we moved onto

the architect, who drew up our ideas. Through a process of discussions, ideas

that were bounced around and problems thrashed out. Ultimately we came up with the plans to be

put into the planners.

These were all stamped and passed in August 2015

As previously mentioned, we then moved onto getting the building warrant from the building standards department of the council.

But we had to get all the details checked first by the structural engineer.

The original idea was to have a few steel pillars supporting UB universal beams that

cantilevered out into fresh air. Giving the impression that the house floated

in mid air. Too may architectural programmes watched and admired.

It soon came to life that the beam sizes would be massive.

So big that they would have required craning in. Another difficulty living over the water and up the side of a mountain (hill- not quite a munro). Its virtually impossible to get them into our area, they have to come

over the ferry, then there is the cost.

So we down sized and then needed more posts. Not a

problem as long as they don’t break up the room. In fact one did and does, but

its in the ground floor area. We can build round it.A problem over come. Or so we thought. But the engineer then felt it was necessary to add steel in the wooden kit home. Posts tying into the base steel that thread through the centre of the timber panels. A ring of steel then capped this off to hold it all together.

Even the roof structure didn't miss out on the steel.

The cathedral roof needed a steel beam and a steel truss.

Our first quote came in at £27k A massive expense. Fortunately, we ended up with a realistic price with a steel broker from Glasgow providing the steel and a local Dunoon fabricator cutting and welding everything on site.

The Kit home manufacturers, thought it was unnecessary and overly complicated, plus vastly more expensive. They even got their own engineer to recalculate and come back and say it was unnecessary. But ultimately, it was proved that our location was very susceptible to wind and uplift. So we decided we had to bite the bullet and go with it.

The price of steel went up, and therefore the overall cost. We still haven't received the revised cost for the kit build.

Next question was the retaining walls on the ground floor-

Lots of variations were

looked at, and eventually we came up with Gabion baskets. The steel mesh cages

that are filled with stones, and used as blocks, one on top of each other.

With the site being

in an area of slate, we thought it would be attractive and in keeping to fill

these with the same material. Furthermore the cost of the cages and the infill

was fairly inexpensive, especially once you remove the labour involved with

laying blocks or brick.As time went on, it was apparent that we needed blockwork to support the visqueen tanking. So in some respects the gabions were unnecessary. Yet we need to retain the earth, so it was then decided to make a double wall that could be in filled with reinforced concrete. BUT ONCE AGAIN we realised that the cost of the concrete was far greater than the alternative of the gabions. Pluus you still needed a second skin of block to hold the visqueen in place. You also had to fit it all out on the inside with a timber cladding.

So we are still investigating the cost merits.

Comments

Post a Comment